– specialized on heavy duty roll bending machines and for example flanking presses for dorn bending

– special application areas are all tanks and containers, ship industry and wind turbines.

– Italian family business since 1927

– specialized on heavy duty roll bending machines and for example flanking presses for dorn bending

– special application areas are all tanks and containers, ship industry and wind turbines.

– Italian family business since 1927

Turkish Sahinler has large selection of three and four roll bending machines, with excellent quality-price ratio.

https://www.sahinlermetal.com/en/product-category/9/plate-bending-machines

For profiles from a bending length of 3 to 12 metres (9 to 40 ft.) and a material thickness of up to 1.5 mm steel (15 gauge).

For profiles from a bending length of 4 to 8 metres (13 to 26 ft.) and a material thickness of up to 1.5 mm steel (15 gauge)

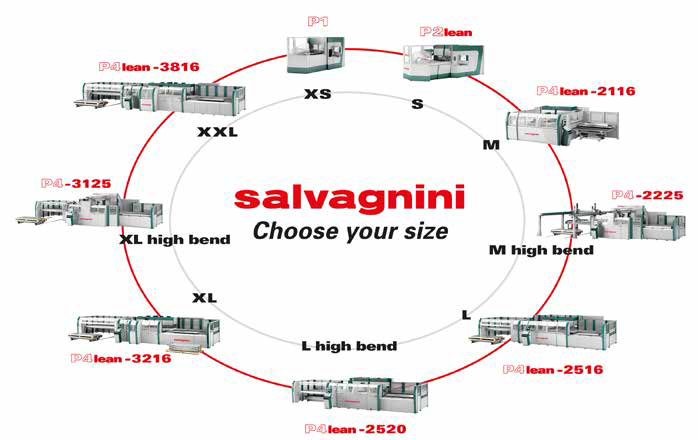

Sheet metal parts ready with one go without test pieces in Flexcell production cell, which can be built modularily around customers personal Lean- needs.

In sheet metal bending flexbility and productivity is combined in P4-Lean-bending automation machine and B3-hybrid

Lean panel benders are providing finished bent parts fully automatically, thanks to freely programming, in variable batches, even one off – so that every work piece could be different shape geometry without any set up times. Variations in material features are measured and corrected during bending cycle through patented and unique MAC2.0 (Material Adaptice Correction) technology. System enables that first part is precise and good minimizing material loss.

Thanks to modular construction, panel benders can be configured or equipped acc. to different customer needs. it can be integrated to different work phases, like into automatic storage systems, punching and right angle shearing centers, combi machines, fiber laser cutting or press brakes. For material handling there are several auotmated options available.

Salvagnini Lean panel bender increase efficiency and productivity, because as thump rule, it replaces work load of three to six press brakes. The bigger the panels get and more complex bending geometries are, the bigger difference there is between panel bender and press brakes in terms of cycle time, required number of operators, repeatability or bending quality etc. In best cases, even ten operators per shift are moved from press brake operating to do other tasks in production.

P2Lean panel bender is more ergonomical in loading and unloading of work piece and now also available with Bend and Cut feature (Option Cut), which has been already used with success in bigger models. Bend and Cut feature (Option Cut) can be offred also to P4L-2116 -model.

P1 ja P2 panle benders can be equipped with new P-Robot for part handling. Single items or small batches operator can load and unload manually. For unmanned production robot is used for loading and unloading. No sperate programming of robot is needed, but it is integrated to StreamBend part programming.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.