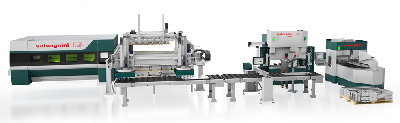

L3 Fiber laser

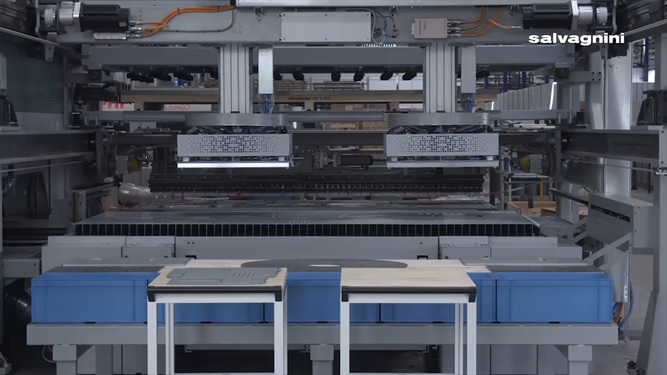

- High-quality optical laser cutting, which has been developed around the fiber technology.

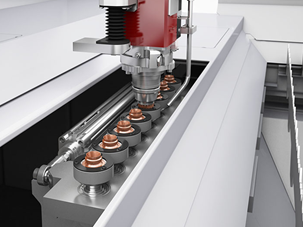

- Patented Dry Cooling -cutting head saves in nitrogen expenses

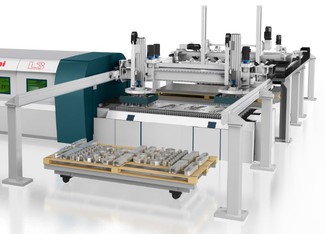

- Laser can be added with device to increase compressed air pressure and it’s being used when cutting 5 mm thickness or less. This saves significantly in cutting expenses.

- Fiber laser saves energy costs by 70% compared with the CO2 laser.

- Minimal need for maintenance, cost per part is more than 50% lower.

- The laser source power 2-10 kW.